LOS ANGELES FOOTBALL CLUB (LAFC)

Welcome, LAFC!

Back in October 2014, Major League Soccer had appointed a new expansion team to the greater Los Angeles Area after Chivas USA shut down its operations three days prior. Almost one year later, the Los Angeles Football Club (LAFC) officially became the newest MLS soccer club in Los Angeles, led by businessman Henry Nguyen, film producer Peter Guber, and former National Basketball Association executive Tom Penn.

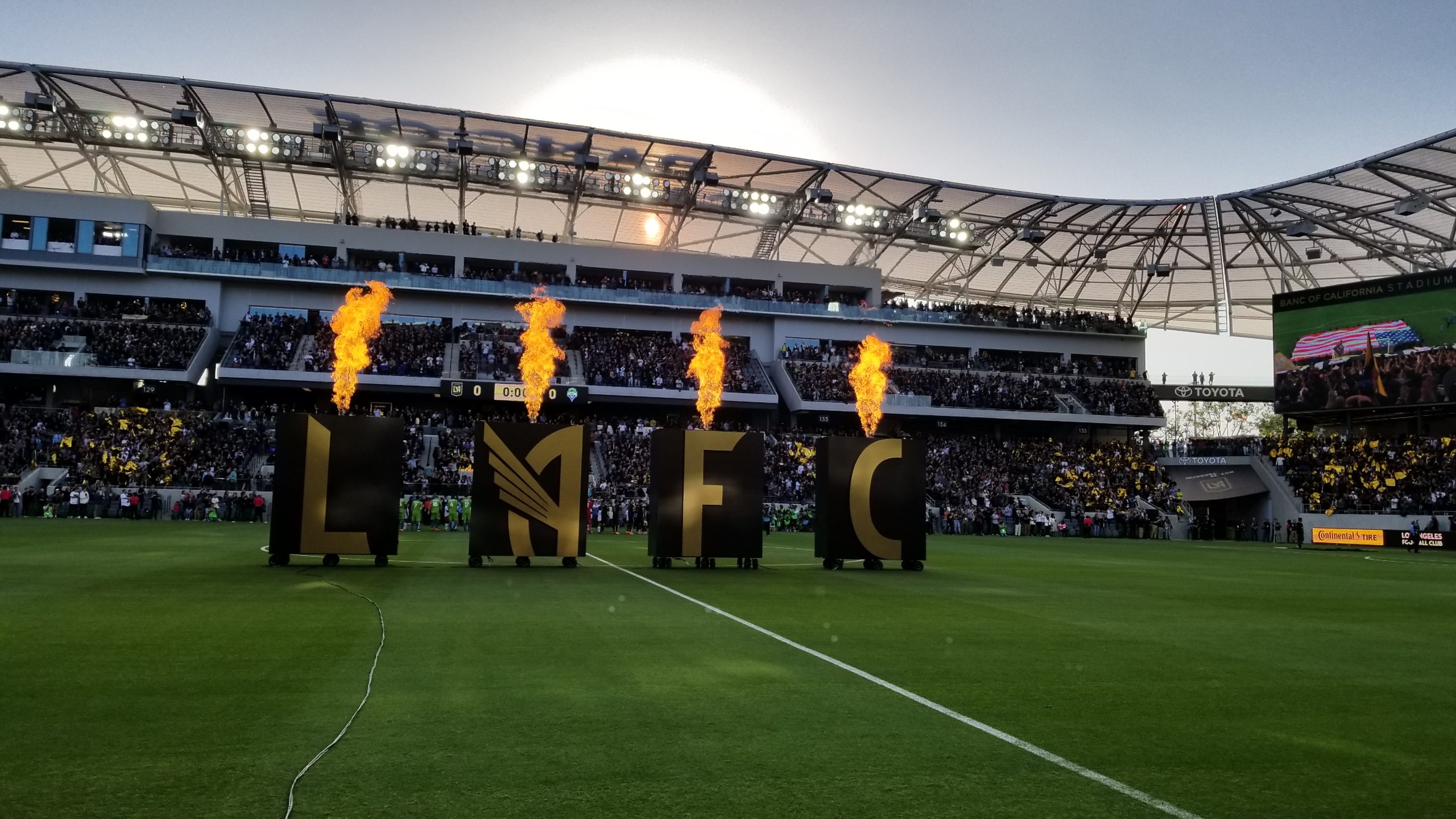

On April 29, 2018, LAFC played its first home game against the Seattle Sounders less than two weeks after the expansion team officially opened the Banc of California Stadium. The first open-air stadium in Los Angeles since 1962 is able to hold 22,000 spectators.

To compliment the new field, LAFC needed to establish a stunning opening ceremony at every home game. Knowing Gallagher Staging had already exceeded the expectations of Image Engineering in the past, there would be no question for the two to collaborate once again.

Building From A Prior Relationship

Gallagher Staging worked with Image Engineering in 2017 to fabricate the tunnel for the Los Angeles Chargers. Manager of Gallagher Manufacturing Jonathan Perez first established this close relationship by doing what we do best – taking utmost care of the client.

With each project, Perez always ensures Image Engineering they have the turn key product ready to present to the client. From there, the client can easily add the other elements needed such as pyro or lighting without any confusion. Gallagher made sure to also create a product to maneuver with ease.

All About the Details

Image Engineering presented Gallagher Staging with a simple drawing of a pyro cart – a box with wheels, a hole on top to carry the pyro head or flame tower and an access hole on its side. After several design discussions between the two teams, Gallagher Staging began with the custom cart wheels, Perez’s favorite detail of the project.

After originally purchasing wheels, our team discovered another vendor that was able to create the same wheel for half the cost. We spent the money saved in adding extra details & making the wheels stronger overall. Some of this extended budget was spent on powder coat and additional CNC details.

Instead of bolting the bottom of the wheels, Perez recessed them two inches so the wheel would be closer to the actual pyro head – this created a low-profile look. Perez transformed the inside bolt into a stronger bolt and removed the rims and tire in order to powder coat the wheel black. They changed all hardware to Grade 8 & pin striped the wheel gold to match the same gold from the LAFC logo and colors as seen on the video below.

Next, the team scaled the LAFC letters to the cart size, had them cut with a water jet. Then we rolled aluminum and performed tig welding. We conveniently fabricated the cart frame and box to accept the letters with pipe pockets if the client ever wishes to change the letter theme, the box itself, or even complete removal of the letters to add lighting or change the color.

The cart itself was a simple design. The small details such as the door with LAFC logo on it and door handle cut in the shape of a shield really brought the project all together. When someone is underneath the top opening panels, the LAFC logo appears here as well. We also incorporated small details such as these to the access to the pyro head and plugs. A nice touch included the door hinges that were cut in the shape of the eagle shown on the LAFC logo.

As for the gold lettering, LAFC requested a special gold named California Gold we were able to retrieve from a Disney painter in order to create the exact look desired, as shown in the photo to the right.

Overcoming Minor Challenges

Gallagher faced the challenge of achieving the correct satin black finish LAFC requested. There’s flat black, off black and satin black. Gallagher ended up painting the carts three different times to get satin black. The reason? Under UV light one is able to view all the blemishes, such as you would see on a car.

“If I can notice a blemish five feet away, then I can see it from two feet away. Due to the large size, painting the carts three times creates a beautiful finish – it’s like a car,” Perez said.

The very last challenge Gallagher overcame related to transportation. These pyro carts would not fit through our warehouse door – we had to dolly the carts out and lay them flat on two separate trucks. After getting from Point A to B, our team had to flip the carts upright in front of the client onsite. With an immense risk of what could go wrong, the offload was a complete success thanks to the expertise of our riggers and Quality Control Manager Val Grant.

“The guys were super stoked,” Perez continued, “this was a win for them to have the bragging rights of working on another Los Angeles home team. They’re still stoked.”

At Gallagher Staging, we emphasize the team experience that results in a successful project every time.

“You can’t say it’s a one man’s show – we are only as good as how we communicate as a team,” Perez concluded.